Project Galleries – Heavy Industry

Steel Mill Upgrade

Client: Confidential

Value: $5.4M

Project Details: Upgrade and conversion of a non-structural steel mill to a structural steel mill. Upgrades included, 20T Coil Unloading, Induction Heating, Inline Painting, Ink-jet Coding, Bundler Reject/line re-integration, Pack Turn-around, Product Storage Racks, Tooling and Transport Racks/Coil Racks, Transformer & MSB upgrade, PLC Networking/Safety PLC Integration, Paint Treatment Plant and Safety Guarding.

Services Provided: GRG provided design, drafting and project management services throughout all phases of the project, from concept to completion.

Semi-Mobile Sizer Plant Project

Client: Confidential

Value: Confidential

Project Details: New semi-mobile sizer stations for coal mines in Cullen Bullen NSW area. Project included Front End Loader Ramp, Feed Hopper complete with Wear Plate Liner, plant structure including platforms, stairs, access ways and concrete foundations, incorporation of MMD Primary and Secondary Sizers and Elton Conveyors.

Services Provided: GRG provided overall design certification and drafting services. GRG facilitated the geotechnical investigation onsite. GRG’s Civil Engineers completed the foundation design and created Scope of Works documentation for the procurement process.

Custom Design Platforms

Client: Confidential

Value: Confidential

Project Details: The client required custom designed platforms specifically tailored for the manufacture of dragline buckets for the mining industry.

Services Provided: GRG provided full design and drafting services. Workshop drawings were provided for manufacture.

Steel Tube Processing Bundling Upgrade

Client: Confidential

Value: $5.5M

Project Details: Installation of OEM equipment for saw runout, induction heating and tube bundling, supported with locally designed equipment to integrate into an existing operational facility. The project aim was to automate tube packing on the line, increase production rate to max mill speed, and integrate safety system upgrades commensurate to current Australian standards. Associated processes and mechanical and electrical service upgrades including 2 x 14t transfer trolleys, finished goods warehouse racking, a cooling tower and power factor correction were included.

Services Provided: Project scoping and budget preparation for capex submission, utility audits to assist project justification, compilation of URS & SOW’s for mechanical equipment quotation & supply, design and drafting for warehouse extension, drafting for complete equipment layout, detailed timeline and cost tracking preparation, co-ordination and supervision of onsite installation works inc. WH&S & JSEA requirements, regular PM tasks, hit list management etc.

Condition and Failure Mode Report of Equipment Involved in an Incident

Client: Government Agency

Value: Confidential

Project Details: Assess condition of Equipment involved in an Incident and Whether Equipment Failure was a contributing factor to the incident.

Services Provided: Onsite inspection and assessment services, followed by submission of a report for the agency describing the analysis and findings.

Other Recent Heavy Industry Projects

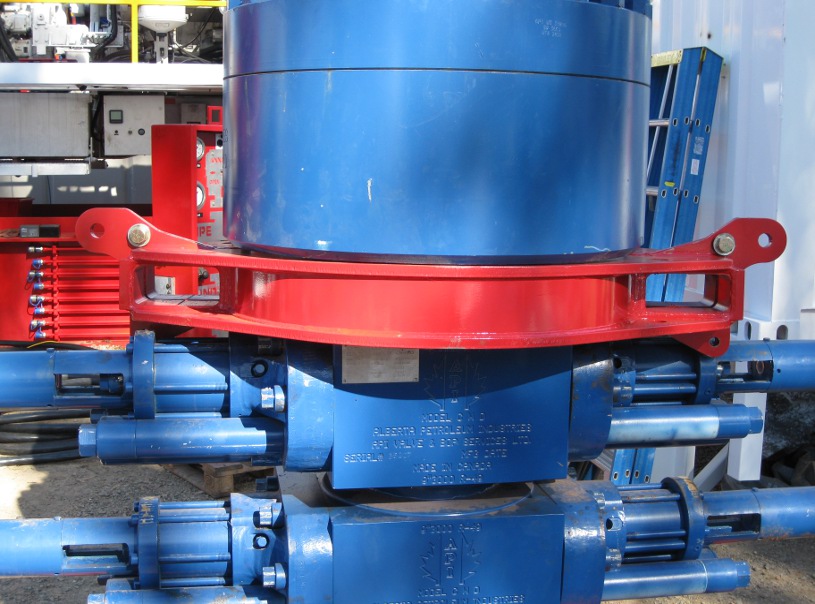

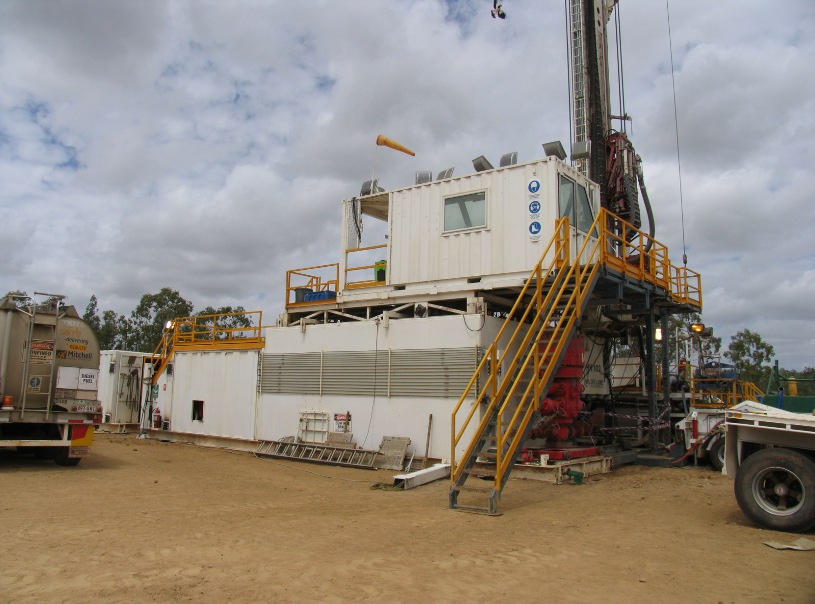

- Lucas Mitchell - Drill Rig Spreads

- Dulux - Pipe Bridge Structure

- Tyco Water - Crane Steelwork Upgrade

- Platforms, Structures and Lifting Devices